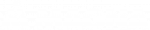

Using advanced automation, we seek to positively influence work processes and environments in order to make the most effective use of resources and experiences.

Since 2023, we are exclusively focussing on RoboLive®, our software solution for commissioning, analyzing, and quality assurance of robotic production processes.

Our goal is to help all robot-supported production plants worldwide to achieve greater resource efficiency, energy savings and reduced effort in order to contribute to a more sustainable world.

PLANNING

Project management support and specification development.

DESIGN

Electrical system design and schematics drawing.

PROGRAMMING

Application, controls and robot programming.

TRAINING

Ramp-up production support and specific training programs.

COMMISSIONING

Virtual and on-site commissioning of controls

and industrial robots.

The company was founded in 1970 when few computers existed outside universities and the military. All controls and logic were hardwired and massive cabinet walls with that technology inside were installed in production environments. From then on everything became smaller and shifted from hardware to software solutions.

Currently, programming and commissioning are becoming one and are shifting from being present at the equipment to virtual. The next logical step is to return to being present at the equipment but this time with augmented reality. We aim to help manufacturers integrate technology and meet the challenges posed by Factory 4.0.

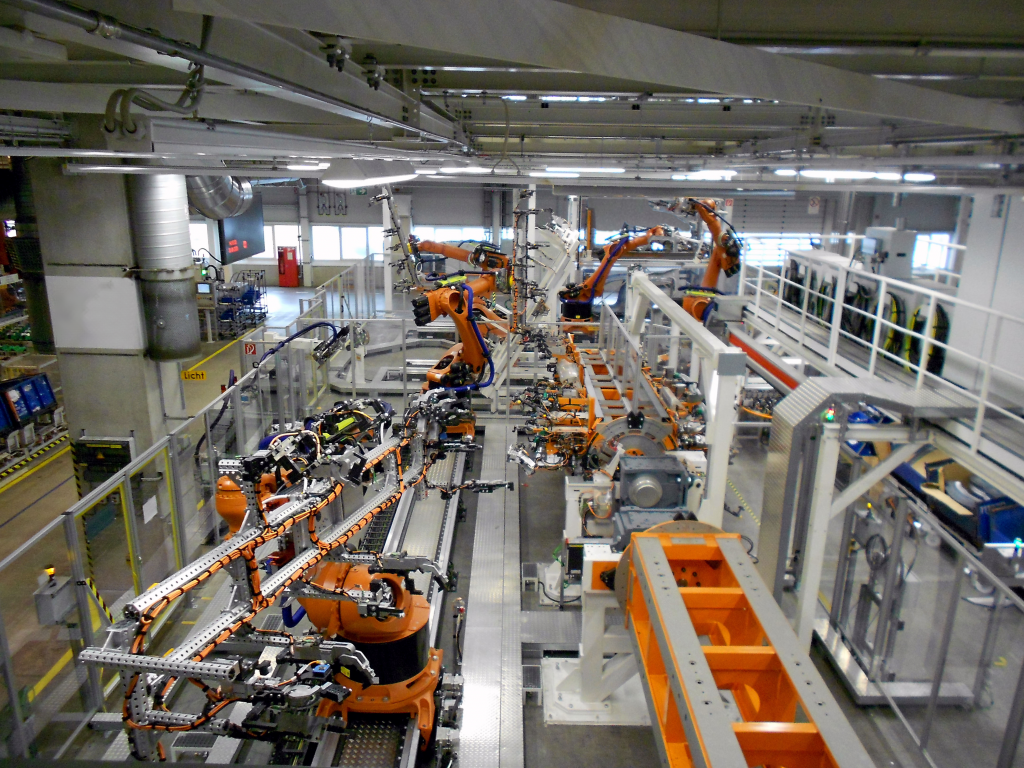

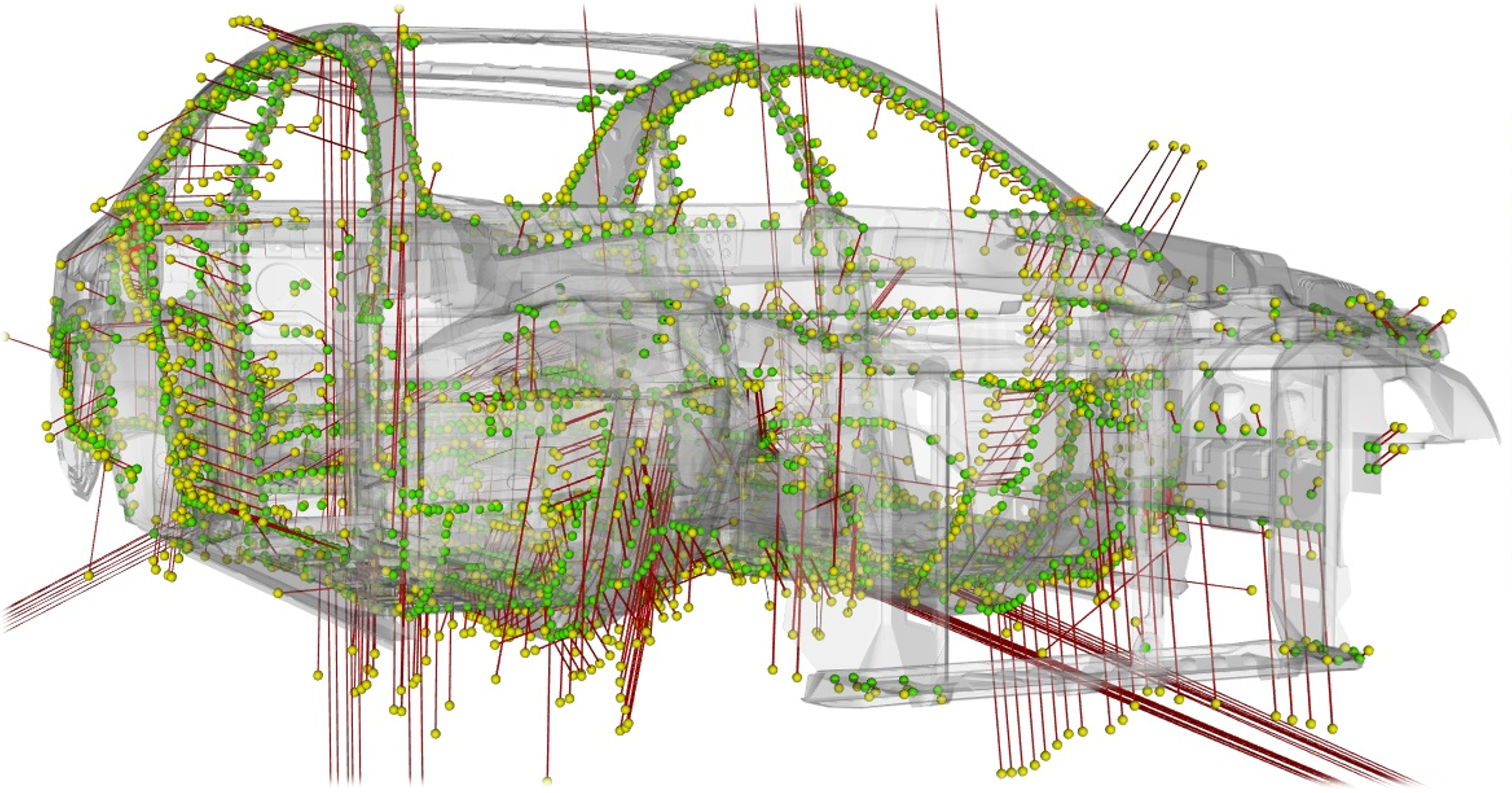

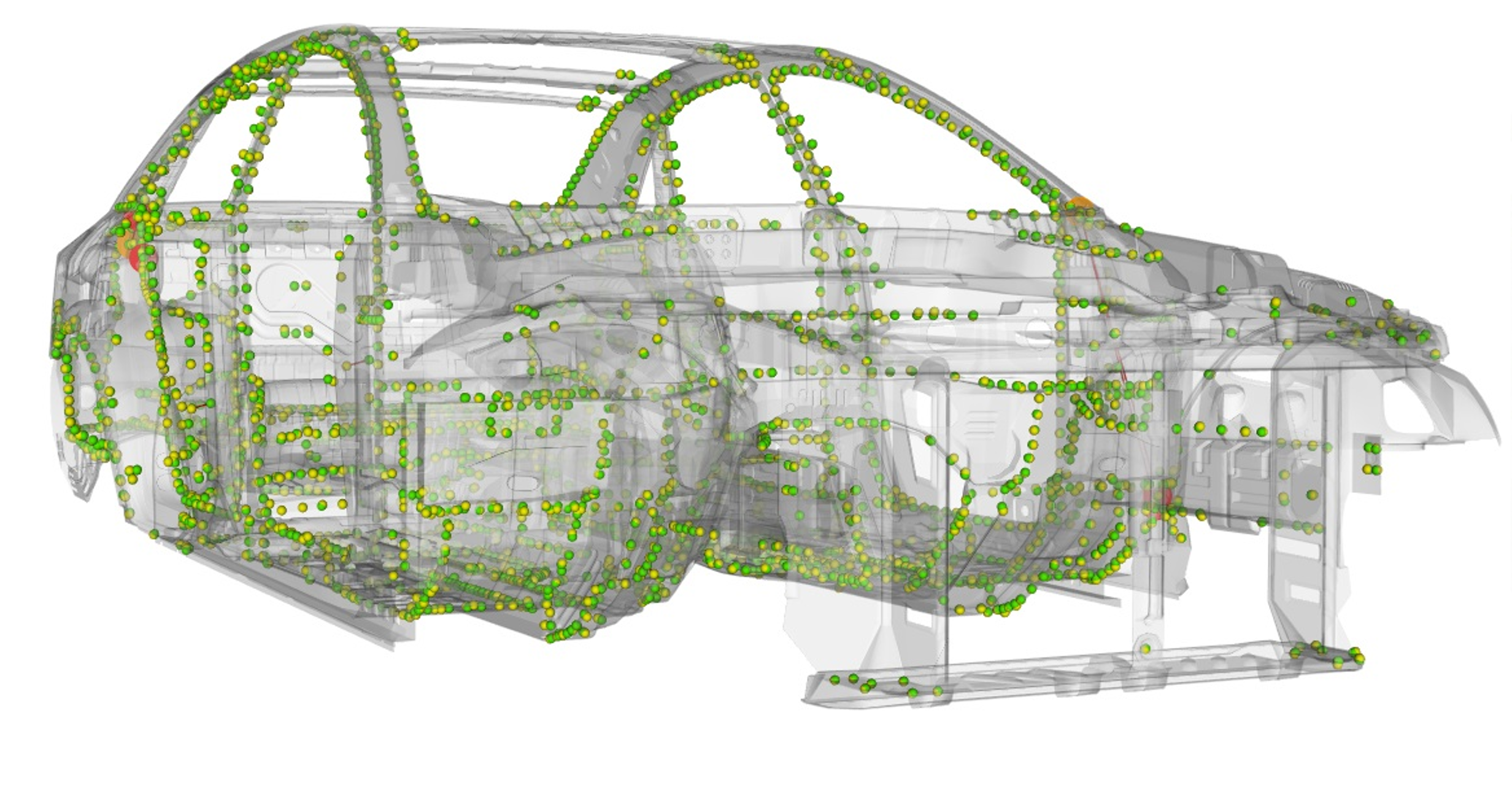

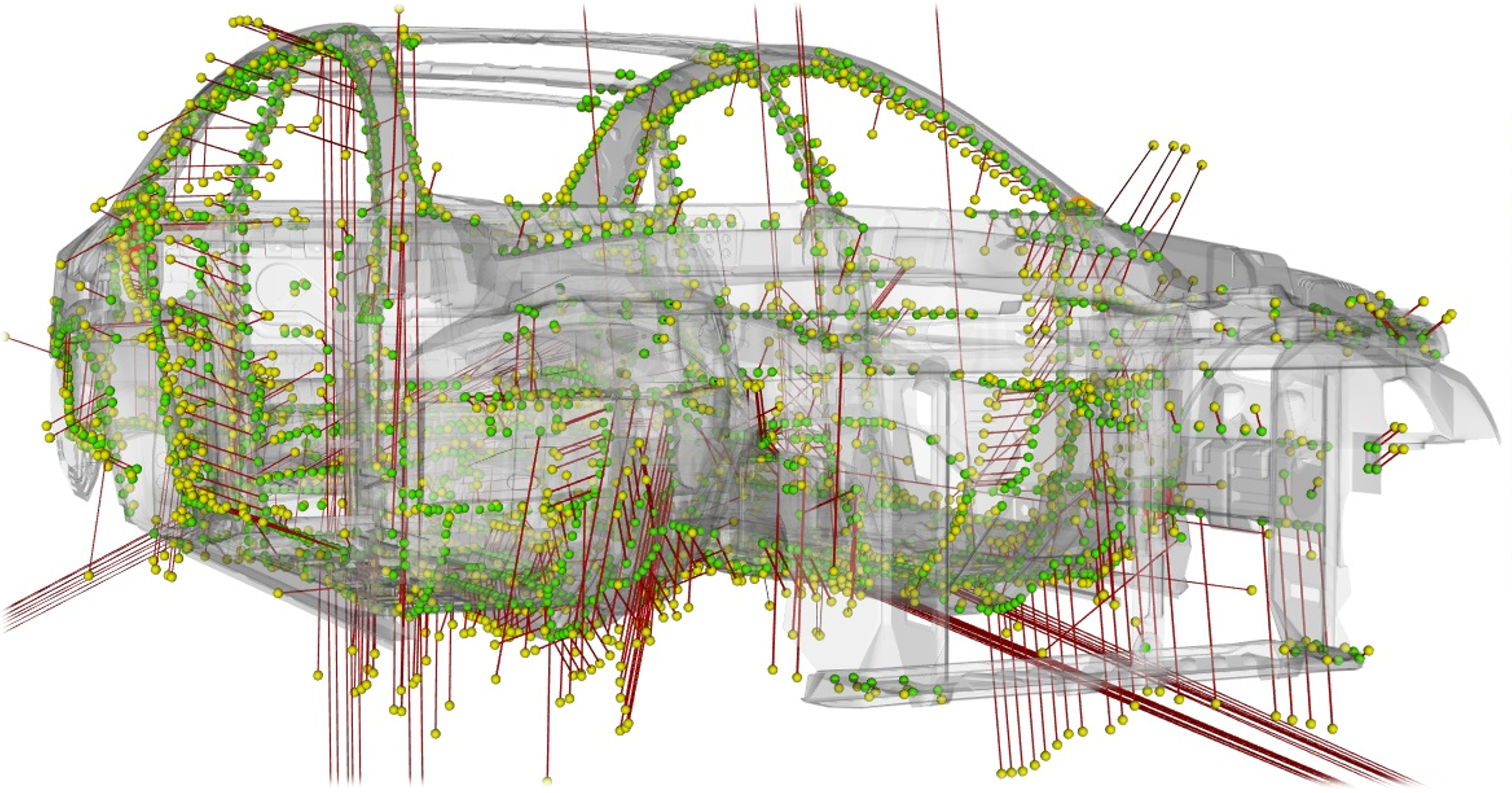

RoboLive® is our solution for the commissioning, analysis, and quality assurance of robotic production processes, which we originally developed to aid our own commissioning projects.

RoboLive® includes five elements for identifying, preventing, and eliminating weak points before and during production. Integrated into the local network, the software automatically retrieves the actual process data from robots, connects them with the planned nominal data, and generates insights and understanding of the manufacturing process. The visualized results are available to all users at any time.

In combination with our personal support, we guarantee individual solutions both in pricing and in the integration and implementation of the products and standards.

Our engineers are standing by to help you tackle automation challenges of any size. Reach out today for a consultation, quote, or more information.

NORTH AMERICA

Dressler Automation Corp.

102 Jordan Drive

Chattanooga TN, 37421

(423) 509-0268

usa@dautomation.com

EUROPE

Dressler Automation GmbH

Braunschweiger Straße 20

38170 Schöppenstedt

+49 5332 9306-0

deu@dautomation.de

Get an up-close look at the software solution that’s changing the way manufacturers interact with their production robots.